Products

There are currently around 60 dairy PROducts in Germany that are entitled to use our PRO WEIDELAND label, as they are made using pasture milk in line with our criteria. Here you can see a selection of the products:

Pasture milk

Fresh pasture milk? No problem. Our partner dairies are committed to our sustainable and transparent approach to pasture farming.

aPROpos:

Did you know that it takes no time at all from collecting the pasture milk from the PRO WEIDELAND farms to the chiller cabinet?

Depending on the size of the dairy herd, milk is collected from our PRO WEIDELAND farms every day or every two days. Once the milk has arrived at the tank in the dairy, it is usually processed on the same day. To ensure perfect quality, the milk is checked again after production and is then ready for collection from the warehouse. If there is an immediate demand, the milk is delivered on the same day and, depending on the customer’s logistics process, can reach the supermarket’s chiller cabinet on the same day.

How is the separation of the flow of goods ensured?

Farmers are categorised by the dairies according to the type of milk they collect. For example, there are collection rounds for conventional milk, organic milk and our pasture milk. This means that the individual types of raw milk are categorised by type. They arrive at the dairy in different tanks. Here, the separation of the flow of goods is ensured via different tanks, filling lines and production sequences.

Which control mechanisms are in place where and when?

Before the pasture milk reaches the dairy, it is tested for antibiotic residues. In addition, the ingredients – such as fat and protein – as well as the content of somatic cells and germs in the milk are checked. Samples are repeatedly taken in the dairy throughout the entire production process; these are analysed for a wide range of parameters. In addition, several retained samples from each production batch are stored until the best-before date is reached.

Pasture butter

As soon as you see our seal of approval on the packaging, you’ll know the butter in question is a cut above. And that you can happily spread it on your bread.

aPROpos:

Did you know how pasture milk is turned into pasture butter?

Firstly, the pasture milk is separated into skimmed milk and cream. The cream is then pasteurised and mechanically “whipped” in a butter churn so that the membrane of the milk’s fat globules is destroyed and the fat is released. The resulting buttermilk is separated. The resulting butter is called “sweet cream butter”. For the “mildly acidified butter” variety, cultures are added.

And did you know that it takes 48 hours to produce our pasture butter and that the increased content of low-melting fatty acids in the milk during the grazing season makes our pasture butter particularly spreadable?

How is the separation of the flow of goods ensured?

The collection lorry routes are planned by the dairies so that our pasture milk is collected separately from other types of milk – such as conventional milk or organic milk. At the dairy, the pasture milk is received in separate storage tanks and processed separately in the subsequent production process: For the separation to conventional butter production, we start with our pasture milk after various cleaning processes and then switch to the conventional milk raw material. During the changeover, a proportion of the raw pasture milk always goes into conventional butter production, i.e. the changeover takes place earlier to ensure that no conventional milk raw material ends up in our pasture milk products.

Which control mechanisms are in place where and when?

The pasture milk is analysed in accordance with the Milk Quality Ordinance. When the pasture milk is delivered to the dairy, it is tested for temperature, pH value and inhibitors. In the further course of production, various tests are carried out in accordance with the recipe – e.g. fat content, pH value, water content and microbiological quality. In addition, samples of “German branded butter” are taken during production and in retail for official control in accordance with the Butter Ordinance.

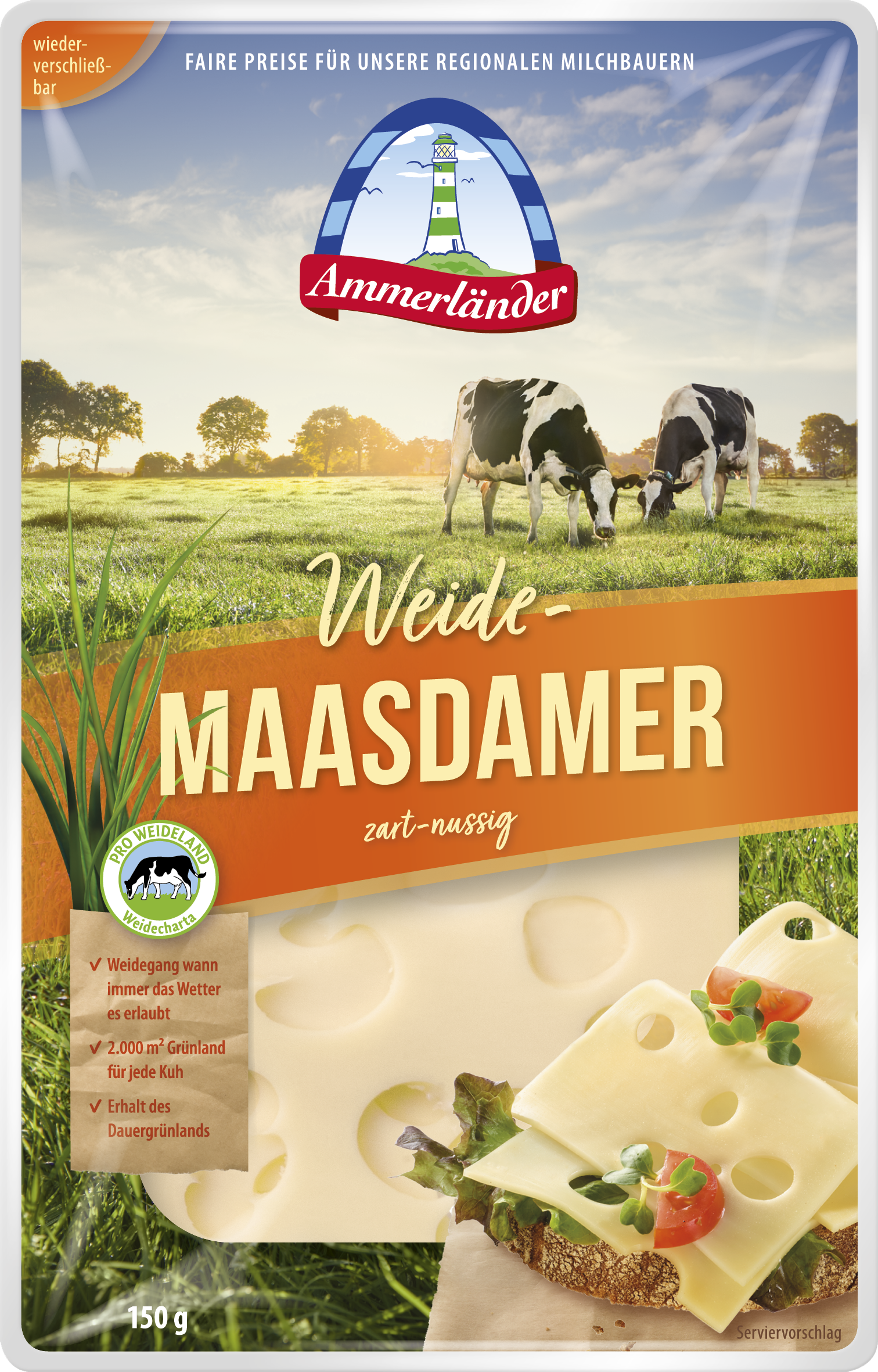

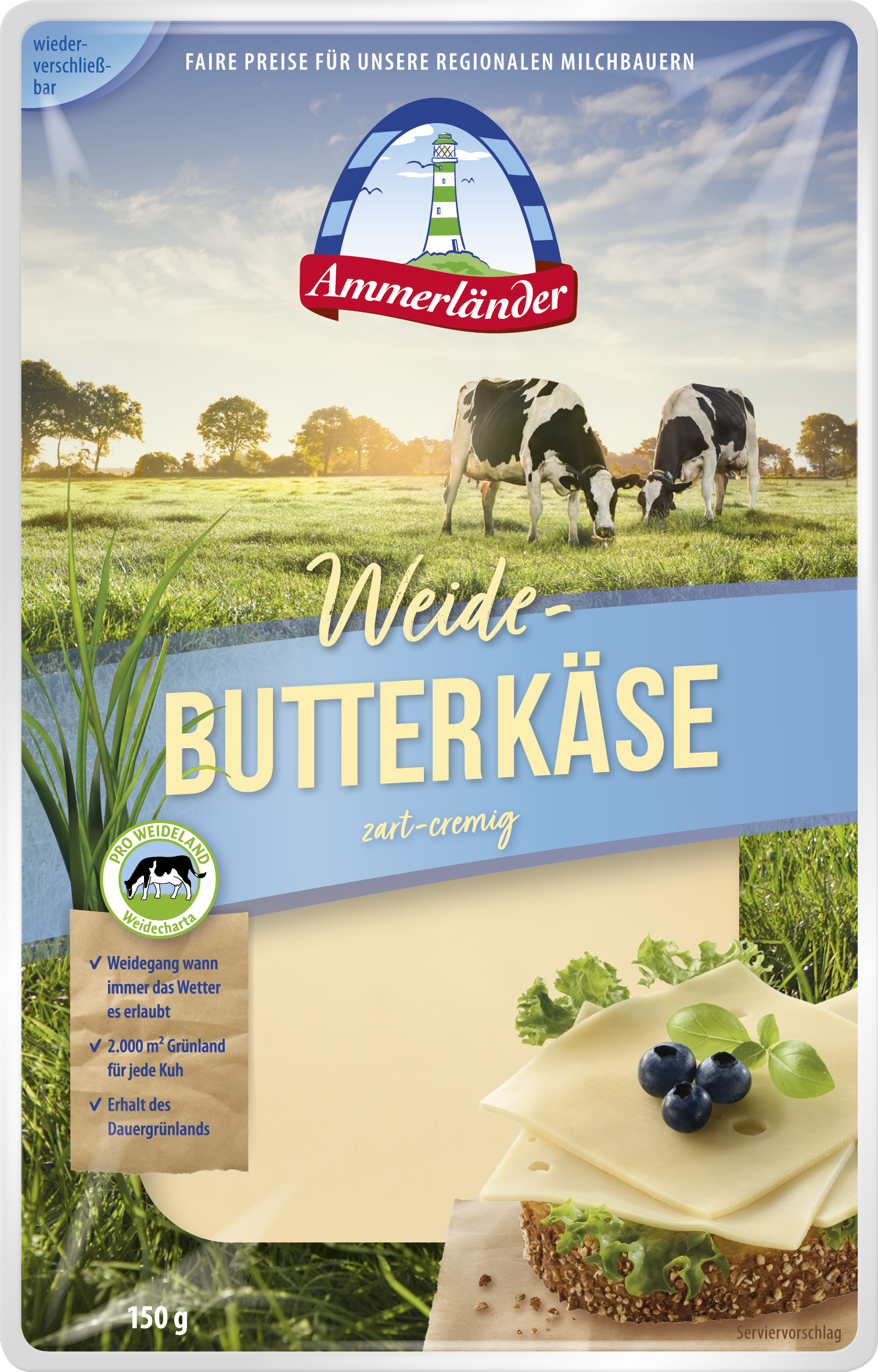

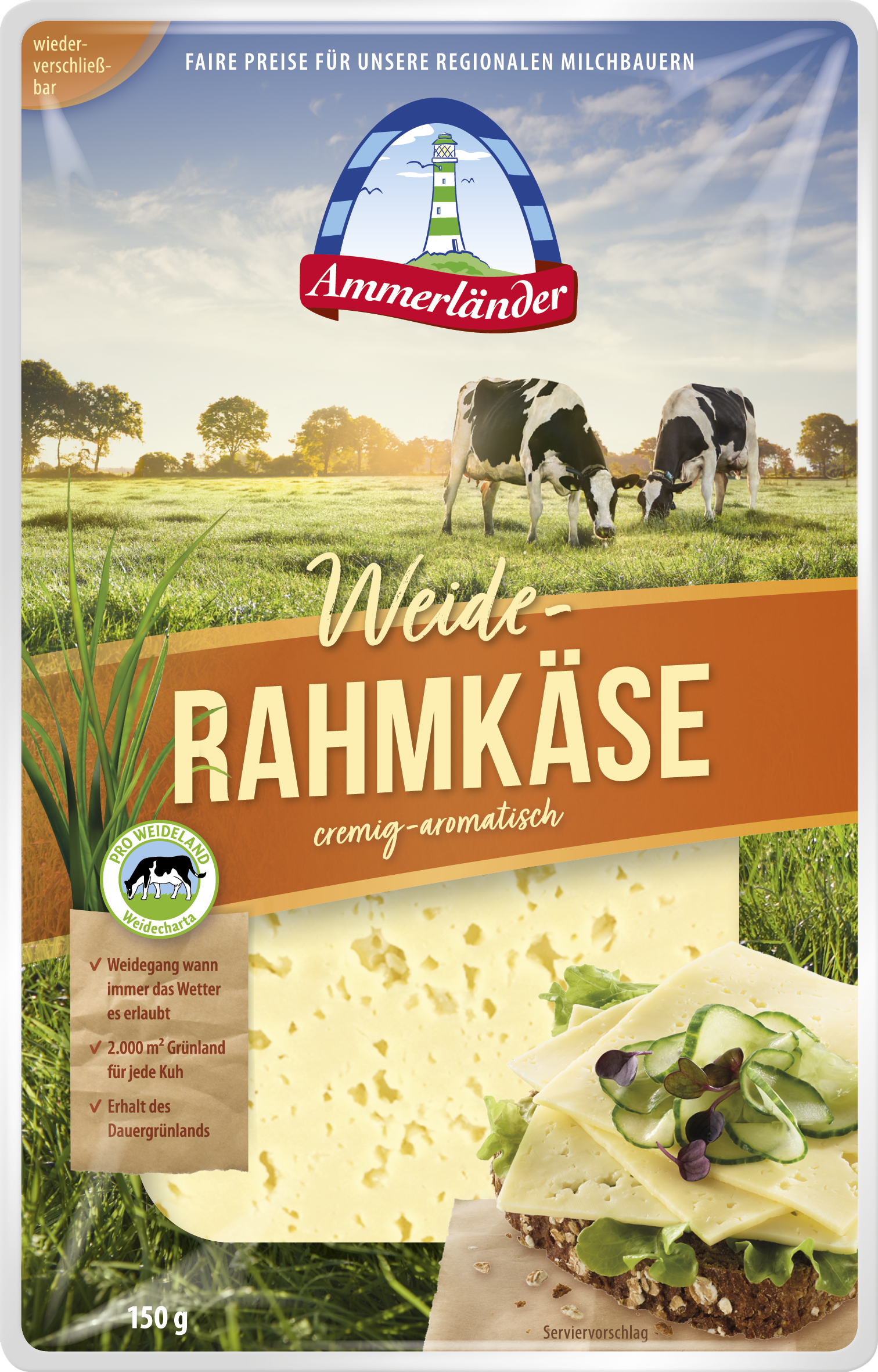

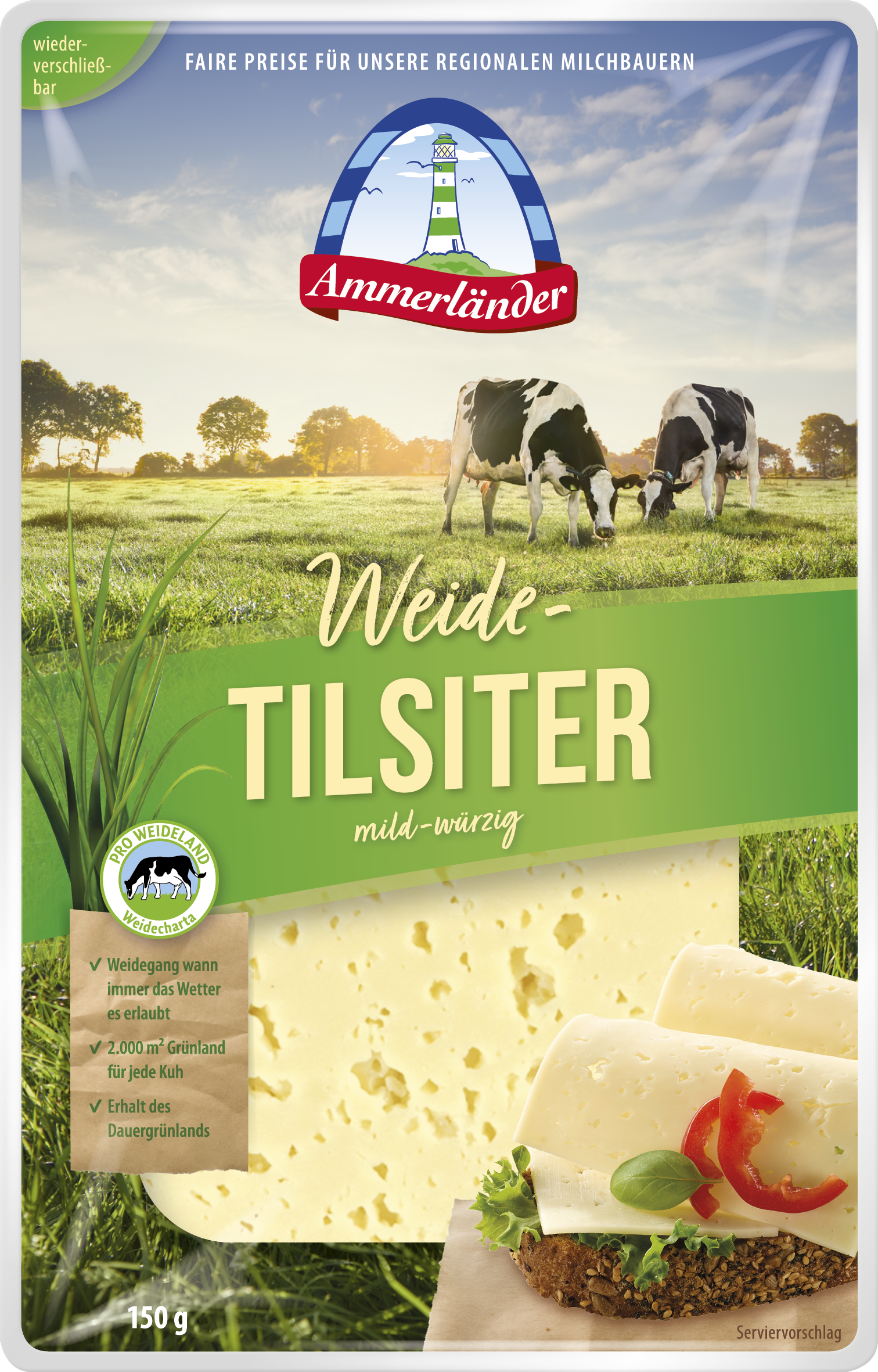

Pasture cheese

From the meadow to your plate. Pasture cheese bearing our label not only tastes delicious, but also helps to ensure sustainable pasture management.

aPROpos:

Did you know how pasture milk is turned into pasture cheese?

To make pasture milk cheese, the pasture milk must first be coagulated. The lactic acid bacteria added to the milk and the rennet coagulate the milk’s protein. This process is called “rennet precipitation”. The resulting gelatinous mass is then cut into uniform pieces using an agitator – the so-called curd is created. The curd is heated during the cutting process. This causes the curd grains to release even more whey, contract and become firm. This process is called “burning”. Once enough whey has been released, the finished curd is filled into a mould. In the mould, the cheese is subjected to pressure – a weight of around 200 kilograms presses the remaining whey out of the cheese and gives it its later shape. The next stage in the production process is the salt bath: the salt solution removes even more moisture from the cheese and promotes the formation of the rind and flavour. Once the cheese has finished its salt bath, the maturing time, maturing location, storage climate and expert care turn it into a delicious speciality.

Pasture meat

Pasture astes good not only in the form of milk – but also in the form of meat. And that is why some PRO WEIDELAND farmers market pasture-raised meat in addition to pasture-raised milk.